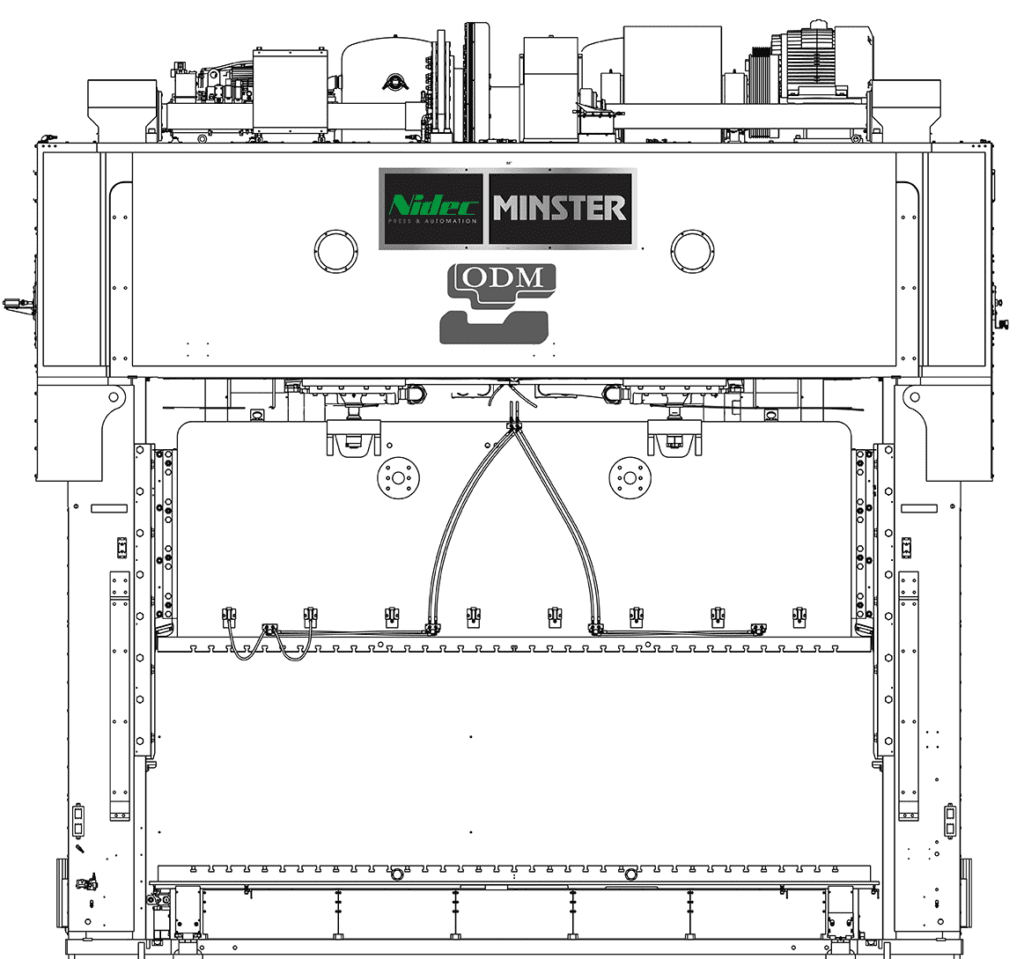

THE NEW MINSTER E2-1200 PRESS

When officials at ODM went looking for a high-quality, dependable large tonnage press, their search ended at Nidec Minster. ODM needed a robust machine, capable of stamping the thicker material, high tensile complex parts it produces, primarily for the automotive industry. The solution was a Minster E2-1200 HeviStamper with a 240-inch left-to-right bed.

READ MORE

With business conditions shifting more and more toward the larger transfer-type parts, ODM had been eyeing not only back-up capabilities for its existing large tonnage presses, but additional capacity as well.

Partially built, and available as a stock machine, the E2-1200 caught the attention of ODM’s owner Chip Michaelsen, and other ODM personnel during a visit to Minster in summer of 2019.

“Our team made a trip to Minster,” ODM Vice President of Sales Jay Michaelsen said. “We were interested in a 700 ton press at the time, and we saw the 1200 ton. That got us thinking about being able to have a dependable solution for our large tonnage parts.”

Specially designed with excellent built-in parallelism for heavy progressive die work, heavy material blanking and forming jobs requiring higher production speed, the Minster E2 HeviStamper Series of presses has earned an unprecedented reputation for quality, durability, and value.

ODM placed the order for the Minster E2-1200, which is expected to go into production in early summer 2020.

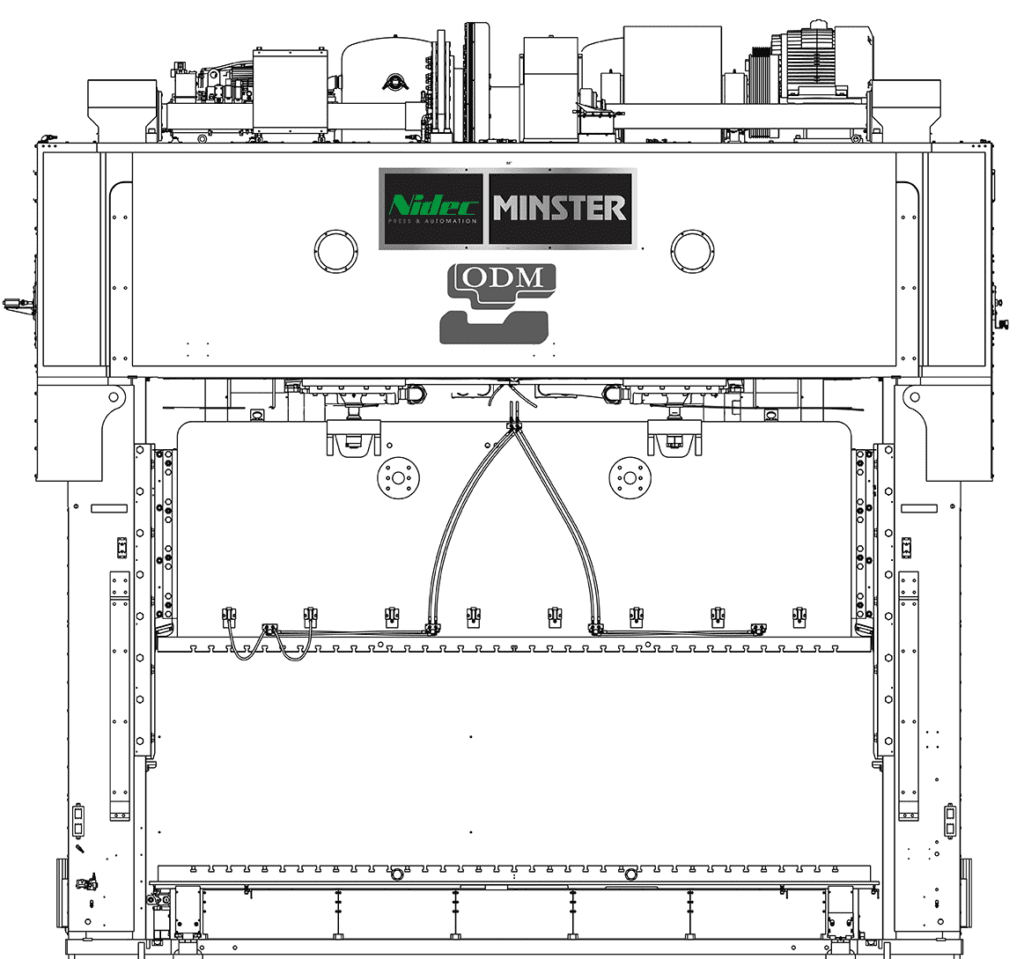

THE NEW MINSTER E2-1200 PRESS

When officials at ODM went looking for a high-quality, dependable large tonnage press, their search ended at Nidec Minster. ODM needed a robust machine, capable of stamping the thicker material, high tensile complex parts it produces, primarily for the automotive industry. The solution was a Minster E2-1200 HeviStamper with a 240-inch left-to-right bed.

READ MORE

With business conditions shifting more and more toward the larger transfer-type parts, ODM had been eyeing not only back-up capabilities for its existing large tonnage presses, but additional capacity as well.

Partially built, and available as a stock machine, the E2-1200 caught the attention of ODM’s owner Chip Michaelsen, and other ODM personnel during a visit to Minster in summer of 2019.

“Our team made a trip to Minster,” ODM Vice President of Sales Jay Michaelsen said. “We were interested in a 700 ton press at the time, and we saw the 1200 ton. That got us thinking about being able to have a dependable solution for our large tonnage parts.”

Specially designed with excellent built-in parallelism for heavy progressive die work, heavy material blanking and forming jobs requiring higher production speed, the Minster E2 HeviStamper Series of presses has earned an unprecedented reputation for quality, durability, and value.

ODM placed the order for the Minster E2-1200, which is expected to go into production in early summer 2020.

Our team made a trip to Minster. We were interested in a 700 ton press at the time, and we saw the 1200 ton. That got us thinking about being able to have a dependable solution for our large tonnage parts.

-Jay Michaelsen, VP of Sales

SUPPLEMENTING THE MINSTER E2-1200 PRESS

ODM currently has more robotic and spot welding stations than presses, as secondary operations have become an important part of the overall solution-based offering.

Additional services include hardware insertion, assemblies, tapping, riveting and part washing.

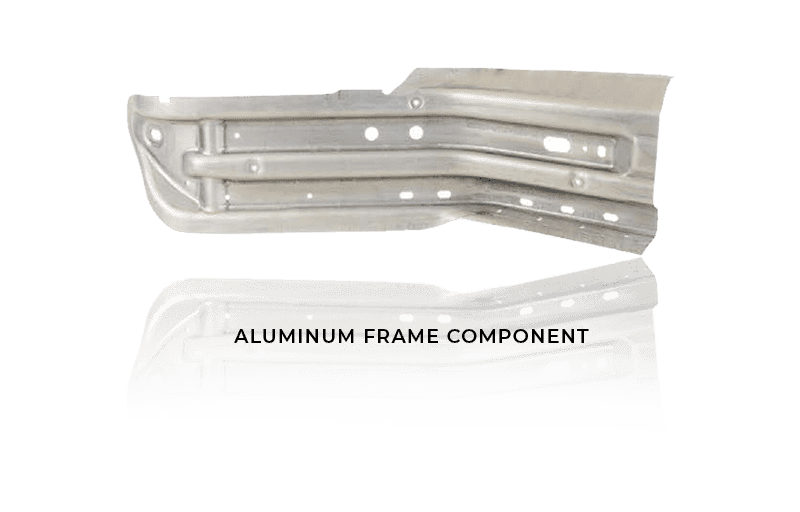

Press capacity ranges from 100 to 1500 tons at ODM with a growing emphasis on more high strength materials. To supplement the new Minster E2-1200 ton press, ODM has purchased a heavy duty CHS feed line, with an extra robust straightener designed to handle some of today’s toughest dual phase materials.

ODM has also purchased a new Gudel Transfer System. With this added capability they will now be able to run most jobs in either the new Minster E2- 1200, or their 1,500 ton as a backup, both having a 240” bed.

SUPPLEMENTING THE MINSTER E2-1200 PRESS

ODM currently has more robotic and spot welding stations than presses, as secondary operations have become an important part of the overall solution-based offering.

Additional services include hardware insertion, assemblies, tapping, riveting and part washing.

Press capacity ranges from 100 to 1500 tons at ODM with a growing emphasis on more high strength materials. To supplement the new Minster E2-1200 ton press, ODM has purchased a heavy duty CHS feed line, with an extra robust straightener designed to handle some of today’s toughest dual phase materials.

ODM has also purchased a new Gudel Transfer System. With this added capability they will now be able to run most jobs in either the new Minster E2- 1200, or their 1,500 ton as a backup, both having a 240” bed.

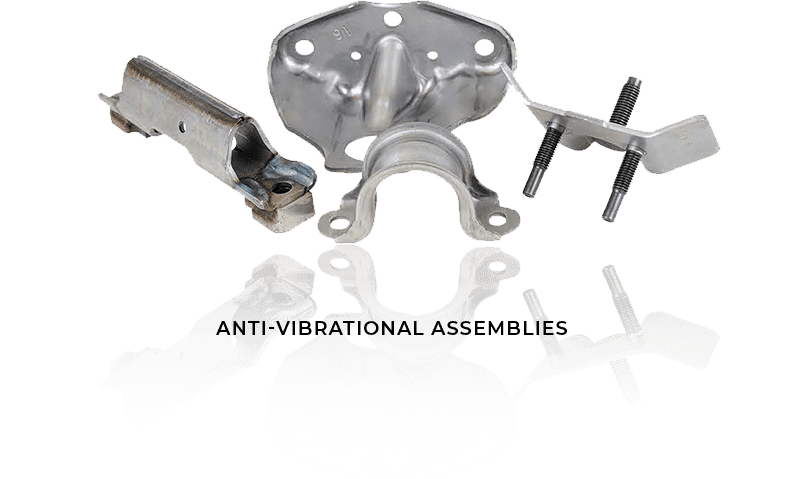

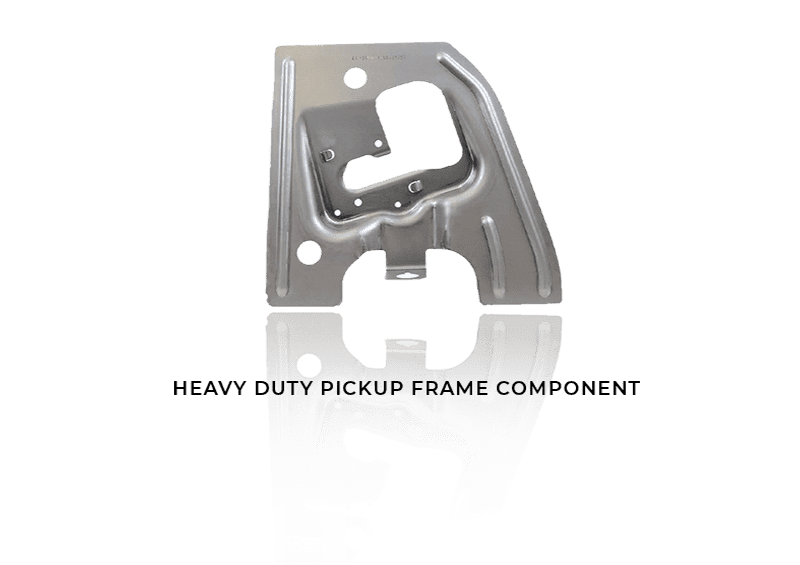

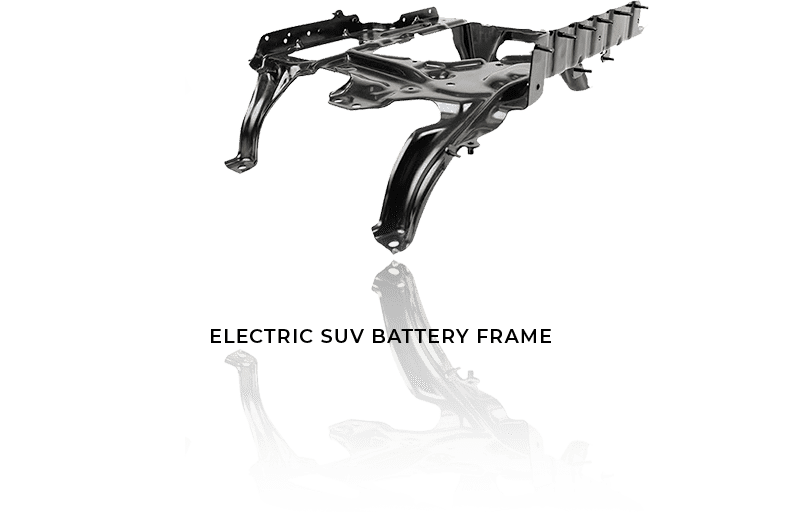

Complex Samplings and assemblies Produced By ODM

EXPANDING INDUSTRIES

ODM’s primary market is automotive, but with the upcoming addition of the Minster E2-1200, the company hopes to expand more into the appliance and hardware industries.

Start a Project

Don’t wait for something to go wrong.

Have parts you’re ready to produce? Don’t risk losing time, money and your reputation. You shouldn’t wait for something going wrong in your parts production to consider a better way. Use a team of professionals you know you can rely on for perfection, every time.